|

Technology

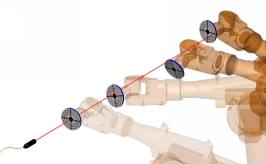

iSiOS uses the native precision of the laser

The patented functional

principle of iSiOS

is based on scanning some precisely straight laser beam with the robot.

When the robot hand is moved along the laser beam, smallest deviations

from the straight line are detected easily. Measurements of these

deviations yield a precise model of the robot by

elaborate mathematical algorithms. The identified robot model contains

all entities which influence the position of the robot hand.

Deformations of the robot arm, zero offsets of the joints or

gravity-induced displacements of the hand are compensated completely

and sustainably in the whole workspace.

iSiOS uses this principle usually

in reverse set-up: the compact, light-weight laser is carried by the

robot and stationary sensors are placed near the workcell

boundary.

Accuracy

Small

errors of the robot are mapped in full size onto the sensor over the

whole range of the laser beam. This is the foundation of the

conceptually

high sensitivity and precision of the system, which could easily be

increased further if

needed - e.g. for the calibration of micro-mechanisms. With two or

three

sensors placed and distributed properly on the boundaries of

the workcell, iSiOS calibration provides

maximum

robot positioning accuracy throughout the complete workspace.

The fundamentally new approach yields decisive technical

advantages

which were reserved to costly laser trackers before

- The large errors caused by gravitation-induced elasticities

and deflections are identified and

compensated precisely. This feature is a key component of the

superior absolute robot accuracy provided by the iSiOS

calibration

system.

- The appropriately sized, patented iSiOS

carbon fiber

etalon with two cost-efficient sensors yields sufficient error

dampening to determine absolute robot lengths precisely in contrast to

measurements

within a restricted area or at a single spot or at

some single calibration-object which may be used by

other approaches.

- During set-up, iSiOS does not

require the use of an additional laser tracker anymore, which was

needed up to now to measure the exact poses of obligatory

calibration-objects w.r.t the robot whenever demanding precision goals

had to be

met.

- iSiOS is highly sensitive also to orientational

errors. When the laser is mounted on the robot hand or tool, the laser

beam functions as an immaterial lever, which amplifies orientation

errors

proportional to distance, yielding maximum orientational accuracy after

calibration.

In

all its accuracy statements, Isios always takes the user defined

tooltip (TCP) into account. As an example, for certain

types of universal, industrial 6-joint robots, absolute positioning

errors at the tip of a tool of 200 mm length can be kept below 0.25 mm

in the whole

workspace including arbitrary changes in the joint-configuration (i.e.

shoulder left or right, elbow up or down, handflip).

Depending

on type, the average overall accuracy

of industrial

robots with workspace radius below 3 m and payload below 500 kg can be

raised up to the exceptionally high level of 0.3 mm and better. The overall

accuracy is the

effective accuracy at the workpiece when the hand pose is specified relative

to the workpiece only. In this case, the absolute pose of the hand

with respect to the world is unknown beforehand but is automatically

identifed by the iSiOS system with the

calibrated robot.

Cost-efficiency

The outstanding scalable sensitvity and high resolution of the system

is founded in the technological concept of the system, not in costly

measurement equipment.

Control of the calibrated robot

Once the parameters of the robot model are identified exactly, the

robot can be controlled exactly. This only requires appropriate

calculations before each

precision move of the robot - the so called

inverse transformation - but no additional measurements during

runtime. Calculation can be executed by the robot control unit. To

obtain superior robot accuracies the extremely

fast iSiOS realtime-precision-control module

is used which may be executed on the robot controller or independently

on a

remote computer.

Compare iSiOS

- iSiOS does not need elaborate,

sensitive optics or precision measurement devices. The scalable

sensitivity of the system and its particular technological concept

guarantee maximum

robot accuracy within the complete workspace - not only for typical

articulated-joint robots but also for cartesian robots, SCARA-robots

and special purpose gantry mechanisms with combinations of rotary and

prismatic (linear) joints.

- All compact components of iSiOS

inline calibration systems remain

installed in the workcell and are readily available when needed. Only

the stationary installation

of all components enables features like

- instant, synchronous

error-diagnosis of all robots of a production line within a

matter of minutes,

- permanent monitoring of all production devices including

mechanisms like rotary tables,

- automatic recalibration and restoration of maximum accuracy

after minor collisions or exchange

of robots within approx. 5 minutes, or

- compensation of wear and tear or temperature effects

concurrent with production.

- Robustness and compactness as well as contactfree, seamless

integration and function in rough obstructed

environments and under low visibility conditions are decisive

advantages in demanding industrial applications.

- The system redeems a large part of its cost already during

set-up and initial calibration of the original production line or

workcell, resp. Teach-In costs become obsolete. iSiOS

is laid out and priced for fast amortisation of stationary

installations in all accuracy-critical cells of a production line.

Compare accuracy, advantages and cost

Are you planning benchmark tests? Isios appreciates to support a

critical evaluation of iSiOS features and

resulting robot

accuracy as well as comparative tests with other calibration

principles.

|

|